Proper wiring of CNC control panels forms the backbone of reliable industrial automation systems. Modern manufacturing environments demand precise control over machining operations, and the electrical infrastructure supporting these systems must be designed with meticulous attention to detail. Understanding the fundamental principles of CNC control panel wiring ensures optimal performance, safety compliance, and long-term operational reliability in demanding industrial applications.

The complexity of modern CNC systems requires systematic approaches to electrical design and implementation. From power distribution to signal routing, every aspect of the wiring infrastructure contributes to the overall system performance. Manufacturers increasingly rely on sophisticated control architectures that integrate multiple subsystems, making proper wiring practices more critical than ever before.

Professional implementation of control panel wiring directly impacts production efficiency, maintenance requirements, and operational safety. Organizations that invest in proper electrical design practices typically experience fewer unplanned downtime events, reduced troubleshooting time, and improved overall equipment effectiveness. The initial investment in quality wiring practices pays dividends throughout the equipment lifecycle.

Fundamental Design Principles

Power Distribution Architecture

Effective power distribution within CNC control panels begins with understanding the various voltage levels required by different system components. Primary power circuits typically operate at higher voltages for motor drives and main system power, while control circuits require lower voltages for logic operations and sensor interfaces. Proper segregation of these power levels prevents interference and ensures reliable operation across all system functions.

The selection of appropriate circuit breakers, fuses, and disconnect switches forms a critical aspect of power distribution design. These protective devices must be sized correctly to provide adequate protection while allowing normal operation of connected equipment. Coordination between different levels of protection ensures that faults are cleared at the appropriate level without causing unnecessary system-wide shutdowns.

Grounding systems within control panels require careful consideration to maintain both safety and signal integrity. A well-designed grounding scheme provides multiple paths for fault currents while minimizing ground loops that can introduce noise into sensitive control circuits. The integration of equipment grounding, signal grounding, and shielding strategies creates a robust electrical environment for precise control operations.

Signal Routing Strategies

Control signal routing demands careful separation from power circuits to prevent electromagnetic interference that can disrupt system operation. Physical separation through dedicated cable trays, conduits, or panel compartments helps maintain signal integrity throughout the system. The use of shielded cables for sensitive analog signals provides additional protection against external interference sources.

Digital communication networks within CNC systems require specialized consideration for cable selection and routing. High-speed communication protocols used in modern automation systems are sensitive to cable quality, termination practices, and electromagnetic environment. Proper implementation of these networks ensures reliable data transmission between control components and reduces communication errors that can impact system performance.

Emergency stop circuits represent a critical safety system that requires independent wiring paths and fail-safe design principles. These circuits must maintain functionality even under fault conditions and should be designed to remove power from hazardous system components when activated. The wiring of emergency stop systems follows strict safety standards and requires regular testing to ensure continued effectiveness.

Component Integration Techniques

PLC and Controller Connections

Modern CNC systems rely heavily on programmable logic controllers and specialized motion controllers that require precise wiring connections. These devices typically feature multiple input and output modules that interface with field devices throughout the machine system. Proper termination techniques and cable management practices ensure reliable connections that can withstand the vibration and environmental conditions common in manufacturing environments.

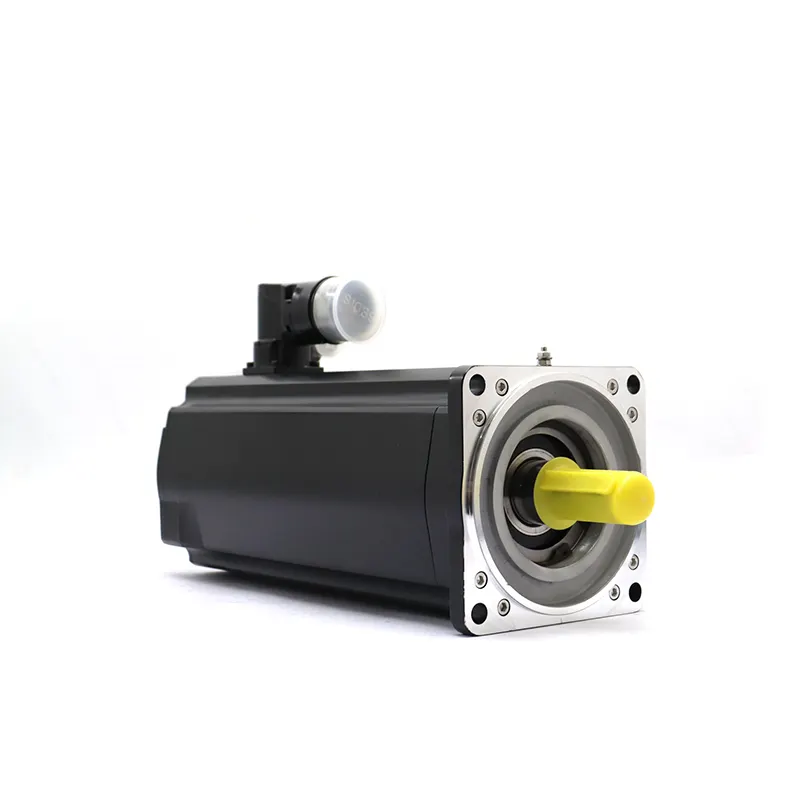

The integration of servo drives and stepper motor controllers requires careful attention to power and signal wiring practices. High-current motor circuits must be properly sized and protected, while encoder feedback signals require shielded cables to maintain position accuracy. The coordination between power electronics and control systems demands systematic wiring approaches that consider both electrical and mechanical requirements.

Input/output expansion modules extend the capability of central control systems but introduce additional wiring complexity. These modules typically connect through standardized communication protocols that require specific cable types and termination procedures. Understanding the requirements of different I/O technologies ensures reliable expansion of system capabilities without compromising overall performance.

Safety System Implementation

Safety-rated components within CNC control panel wiring systems require specialized wiring practices that maintain safety integrity levels throughout the system lifecycle. These components often feature redundant circuits, diagnostic capabilities, and specific connection requirements that must be followed precisely to maintain safety certification. The documentation and testing of safety circuits requires additional rigor compared to standard control circuits.

Light curtains, safety switches, and other protective devices integrate into the overall safety system through dedicated wiring networks. These devices typically feature multiple outputs that provide both safety and diagnostic information to the control system. Proper wiring of these devices ensures that safety functions operate reliably while providing useful diagnostic information for maintenance activities.

Safety relay modules and configurable safety controllers require careful wiring to maintain their safety ratings and functionality. These devices often feature removable terminal blocks and diagnostic indicators that aid in troubleshooting and maintenance activities. The integration of these components into the overall control system requires understanding of both safety requirements and functional specifications.

Installation Best Practices

Cable Management Systems

Professional cable management within control panels improves both functionality and maintainability of CNC systems. Structured approaches to cable routing reduce congestion, improve airflow, and facilitate future modifications or troubleshooting activities. The use of cable trays, wire ways, and flexible conduits provides organized pathways for different types of cables while maintaining proper separation between power and control circuits.

Labeling systems for cables and terminal points greatly enhance the maintainability of complex control panels. Systematic labeling approaches that correlate with system documentation enable technicians to quickly identify circuits during troubleshooting or modification activities. Modern labeling technologies provide durable identification that withstands the environmental conditions common in industrial applications.

Strain relief and mechanical protection for cables entering and exiting control panels prevent damage from vibration, movement, and environmental factors. Proper selection and installation of cable glands, flexible conduits, and strain relief devices protect the electrical connections and maintain the integrity of panel enclosures. These mechanical considerations are particularly important in applications where panels may be subject to vibration or movement.

Testing and Commissioning Procedures

Systematic testing procedures during control panel commissioning verify that wiring installations meet design specifications and safety requirements. These procedures typically include continuity testing, insulation resistance measurements, and functional verification of all circuits. Documentation of test results provides a baseline for future maintenance activities and helps identify potential issues before they impact system operation.

Commissioning activities extend beyond basic electrical testing to include verification of communication networks, safety systems, and integrated functionality. These comprehensive tests ensure that all system components work together as designed and that safety systems respond appropriately to various fault conditions. The systematic approach to commissioning reduces the likelihood of problems during production operation.

Performance validation during commissioning includes testing of system response times, accuracy of positioning systems, and overall coordination between different subsystems. These tests verify that the wiring infrastructure supports the intended system performance and identifies any limitations that might impact production operations. Documentation of performance characteristics provides valuable information for ongoing optimization efforts.

Maintenance and Troubleshooting

Preventive Maintenance Strategies

Regular inspection of wiring connections helps identify potential problems before they cause system failures. These inspections typically focus on terminal tightness, cable condition, and signs of overheating or corrosion. Thermal imaging techniques can identify hot spots that indicate loose connections or overloaded circuits, enabling proactive maintenance that prevents unexpected downtime.

Environmental factors within control panels can gradually degrade wiring components and connections over time. Dust accumulation, temperature cycling, and humidity variations all contribute to the aging of electrical components. Regular cleaning and environmental monitoring help maintain optimal conditions for reliable operation of control panel wiring systems.

Documentation maintenance ensures that wiring diagrams and system information remain current as modifications are made to control systems. Outdated documentation significantly increases troubleshooting time and creates safety risks during maintenance activities. Systematic approaches to documentation management help maintain accurate records throughout the system lifecycle.

Diagnostic Techniques

Modern diagnostic tools greatly enhance the ability to troubleshoot complex CNC control panel wiring systems. Digital multimeters, oscilloscopes, and specialized communication analyzers provide detailed information about system operation and can quickly identify the source of problems. Understanding how to effectively use these tools reduces troubleshooting time and improves the accuracy of problem diagnosis.

Communication network diagnostics require specialized knowledge and tools to identify problems in high-speed digital systems. Network analyzers and protocol-specific diagnostic tools can identify communication errors, timing problems, and network congestion issues that may impact system performance. These diagnostic capabilities become increasingly important as systems become more interconnected and dependent on digital communication.

Systematic troubleshooting approaches help technicians efficiently identify and resolve wiring-related problems in CNC control systems. These approaches typically begin with reviewing system documentation and recent changes, then proceed through systematic testing of different system components. The use of diagnostic flowcharts and troubleshooting guides helps ensure that all potential causes are considered during problem-solving activities.

FAQ

What are the most important safety considerations when wiring CNC control panels

Safety considerations for CNC control panel wiring include proper grounding systems, emergency stop circuit implementation, and compliance with electrical codes and standards. All power circuits must be properly protected with appropriately sized overcurrent devices, and safety-rated components must be wired according to manufacturer specifications to maintain their safety integrity levels. Additionally, proper lockout/tagout procedures must be followed during installation and maintenance activities.

How do I prevent electromagnetic interference in CNC control systems

Preventing electromagnetic interference requires careful separation of power and control circuits, use of shielded cables for sensitive signals, and proper grounding techniques. Physical separation through dedicated cable trays or conduits helps minimize coupling between different circuit types. Shielded cables should be properly terminated with 360-degree shield connections, and grounding systems must be designed to minimize ground loops while providing effective noise reduction.

What cable types are recommended for different CNC control applications

Cable selection depends on the specific application and environmental conditions. Power circuits typically require THHN or similar building wire for fixed installations, while flexible applications may require SO or similar portable cable types. Control circuits often use shielded twisted pair cables for analog signals and specialized communication cables for digital networks. Environmental factors such as temperature, chemical exposure, and flexibility requirements influence the selection of appropriate cable types for specific applications.

How often should CNC control panel wiring be inspected and maintained

Inspection frequency depends on the operating environment and system criticality, but most industrial applications benefit from quarterly visual inspections and annual comprehensive electrical testing. High-vibration or harsh environments may require more frequent inspections, while clean environments may allow longer intervals between detailed inspections. Thermal imaging surveys should be conducted annually to identify potential connection problems, and any signs of overheating, corrosion, or physical damage should be addressed immediately regardless of the scheduled maintenance interval.